US RACK™ OFFERS A NEW NO-DRILL RACK THAT WORKS WITH THE ACCESSORY RAILS IN TOYOTA AND NISSAN TRUCKS

LAS VEGAS, NV – U.S. Rack has released a new no-drill alternative in truck rack systems at the 2007 SEMA Show in Las Vegas. The new rack called the Rail Rack carries up to 400 lbs. It sits on the bedrails of trucks with conventional fleetside bedrails as well as newer trucks with the Toyota Deckrail system Nissan Utili-track system.

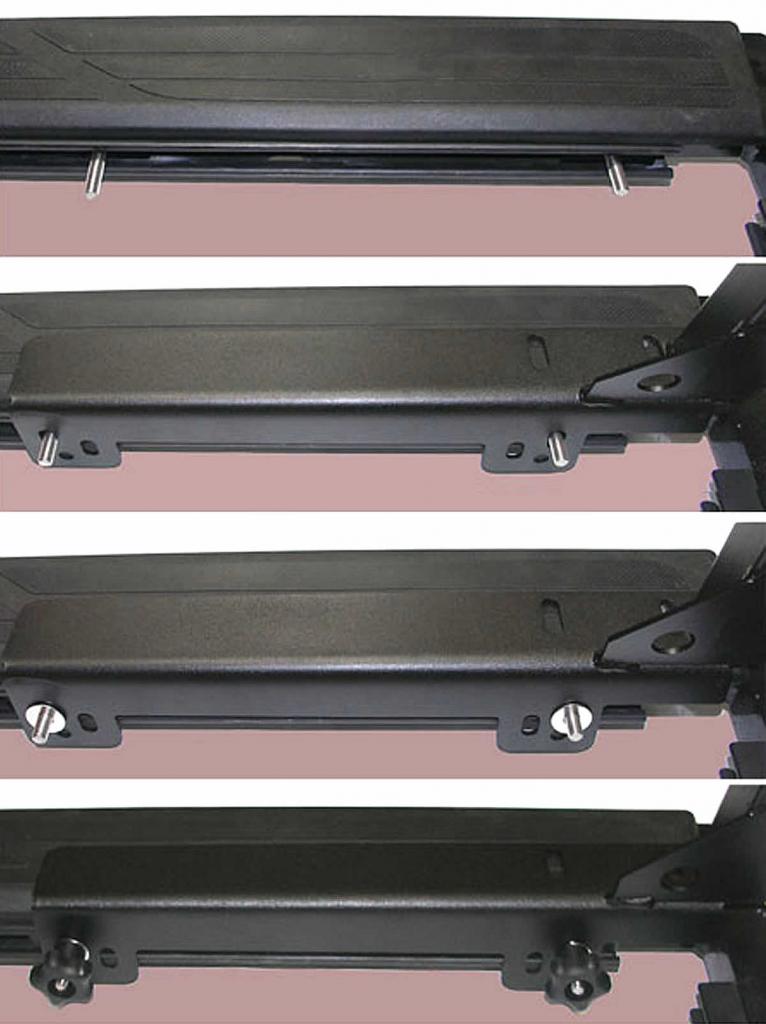

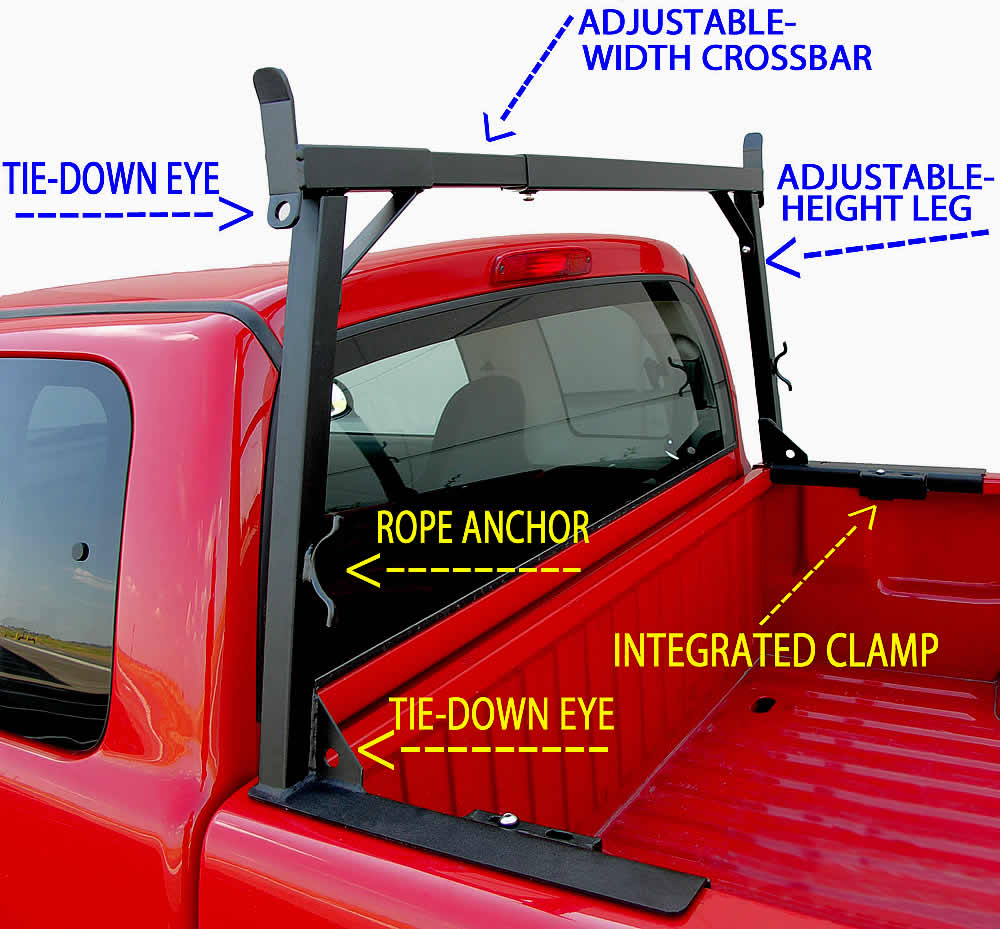

The Rail Rack is made of sturdy tubular steel and consists of two sections. The front section supports a crossbar just behind the cab. This can be used alone as a headache rack or used in conjunction with a second section that supports a crossbar at the back of the bed. The back section can also be moved forward or back along the bedrail to the desired location. The rack easily installs in about 5 minutes without drilling and can be quickly removed and stored as needed. The Rail Rack is also compatible with many OEM Toyota and Nissan accessories such as slide-able tie downs and tool boxes.

Racks are available in carbon steel or stainless steel by special order. Carbon steel racks are powder coated black. Stainless steel racks are powder coated silver gray. Rubbery pads on contact surfaces helps protect truck surfaces.

“Our Rail Rack is a great universal rack truck owners a medium duty rack that easily and quickly installs without drilling or degrading the resale value of the vehicle. This is the type of rack that Toyota and Nissan customers especially have been looking for”, said Chris Green, CEO of U.S.

Rack. “One that is compatible in style and function with the new generation of trucks with accessory rail systems”.

The Rail Rack is exceptionally affordable for the complete two-section rack system. Rail Racks are warranted for a period of one year against all structural defects in materials and workmanship when installed properly

|

|

|

|

|

|

|

Download the Rail Truck Rack Press Release as a PDF Download the Rail Truck Rack Press Release as a Word Document |

|

U.S. RACK, INC., MANUFACTURER OF QUALITY TRUCK RACKS

U.S. Rack manufactures the largest variety of distinct pickup truck rack designs anywhere and leads the market with quality, innovative, multi-functional pickup racks that install quickly with NO DRILLING.

U.S. Rack began, as so many businesses have, in a garage in the Silicon Valley. After taking a large welded rack off his pickup, Chris Green had two problems: (1) a sore back and (2) no place to store the bulky rack. He exclaimed to his wife, Stephanie, “There ought to be a rack that clamps onto a truck and stores easily when you don’t need it.” Out of that insight grew the U.S. Rack business.

Determined to make sure that his designs were sturdy and safe, Chris initially worked with a university engineering department and later with an independent engineering lab to load-test components and products. In 2000, he set up a small shop to manufacture the first production racks and in 2003 built the larger Madera, CA manufacturing plant.

U.S. Rack is still a small business, now located in Southern California and part of the T-REX Truck Product family, manufacturing the largest variety of distinct pickup truck rack designs anywhere and leads the market with AMERICAN MADE quality, innovative, multi-functional pickup racks that install quickly with NO DRILLING.