US RACK™ OFFERS A NO-DRILL HAWAIIAN SAWHORSE RACK™ THAT CARRIES UP TO 300 POUNDS OF CARGO

Madera , CA – U.S. Rack offers the pickup owner a no-drill alternative in truck-bed rack systems. The Hawaiian Sawhorse Rack from U.S. Rack installs in about five minutes, requires no drilling, and can hold up to 300 pounds of cargo – perfect for transporting lumber, ladders, plywood, pipe or other accessories.

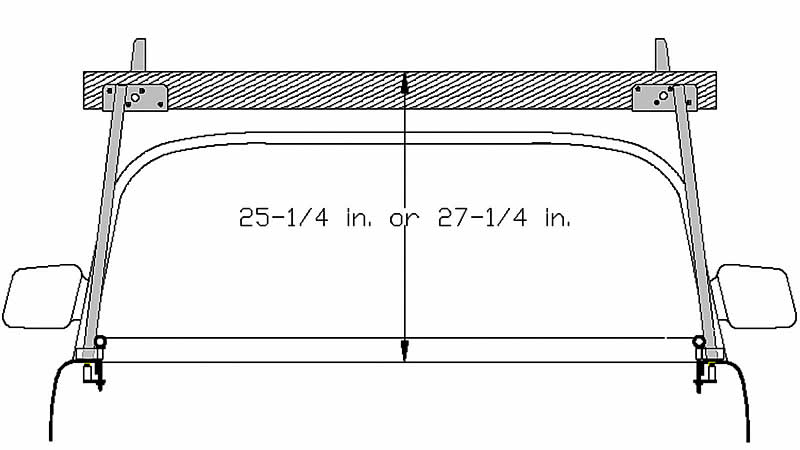

Made of black semi-gloss powder-coated steel, the Hawaiian Sawhorse Rack adjusts to fit any pickup and installs or un-installs quickly and easily using a superior clamping system as an alternative to drilling into the truck body. Weighing less than 35 pounds, it can be removed in less than 5 minutes for use as a sawhorse at the job site, or as a multi-purpose stand when back at the garage.

Padded components protect the side rails and truck bed, and the wood of the rack can be painted or stained to custom-match the truck. Eye-bolts are located at each corner of the rack so cargo can be tied down.

“Our Hawaiian Sawhorse Rack offers the best value in a durable, versatile, sawhorse rack for the pickup owner”, said Chris Green, owner of U.S. Rack. “It’s perfect for the pickup owner who needs a great all-purpose, no-drill rack for their truck bed. Our superior clamping system insures that our rack will stay in place and carry a full load, but can be quickly and easily removed for storage or use as a sawhorse.

The Hawaiian Sawhorse Rack is extremely affordable, priced at around $200, and is warranted for a period of one year against all structural defects in materials and workmanship when assembled and installed properly

|

|

|

|

|

Download the Hawaiian Sawhorse Press Release as a PDF Download the Hawaiian Sawhorse Rack Press Release as a Word Document |

|

U.S. RACK, INC., MANUFACTURER OF QUALITY TRUCK RACKS

U.S. Rack manufactures the largest variety of distinct pickup truck rack designs anywhere and leads the market with quality, innovative, multi-functional pickup racks that install quickly with NO DRILLING.

U.S. Rack began, as so many businesses have, in a garage in the Silicon Valley. After taking a large welded rack off his pickup, Chris Green had two problems: (1) a sore back and (2) no place to store the bulky rack. He exclaimed to his wife, Stephanie, “There ought to be a rack that clamps onto a truck and stores easily when you don’t need it.” Out of that insight grew the U.S. Rack business.

Determined to make sure that his designs were sturdy and safe, Chris initially worked with a university engineering department and later with an independent engineering lab to load-test components and products. In 2000, he set up a small shop to manufacture the first production racks and in 2003 built the larger Madera, CA manufacturing plant.

U.S. Rack is still a small business, now located in Southern California and part of the T-REX Truck Product family, manufacturing the largest variety of distinct pickup truck rack designs anywhere and leads the market with AMERICAN MADE quality, innovative, multi-functional pickup racks that install quickly with NO DRILLING.